To optimize the process of using hydrogen to generate clean energy, Stanford University scientists have spearheaded efforts to develop a cheap and efficient single-catalyst water splitter.

Climate change has concerned world leaders for decades, and scientific organizations have scrambled to develop clean energy methods. Hydrogen has proved to be a promising method of generating energy, but one of the most difficult aspects of hydrogen energy is the inefficiency with which hydrogen can be created.

Yi Cui, an associate professor of materials science and engineering, told the Stanford News Service that their low-voltage, single-catalyst water splitter “continuously generates hydrogen and oxygen for more than 200 hours.”

Catalysts are chemicals that stimulate or accelerate chemical reactions. Cui attributes the water splitter’s low cost to lithium-ion batteries which cheaply create one catalyst: nickel-iron oxide.

“Our group has pioneered the idea of using lithium-ion batteries to search for catalysts,” Cui said. “Our hope is that this technique will lead to the discovery of new catalysts for other reactions beyond water splitting.”

This catalyst plays the role of two separate catalysts: The lithium-ion battery converts the nickel-iron oxide into small particles, and these particles are effective at producing more hydrogen gas.

The single-catalyst water splitter differentiates itself from two conventional methods of procuring hydrogen fuel: using electrolysis and reforming natural gas.

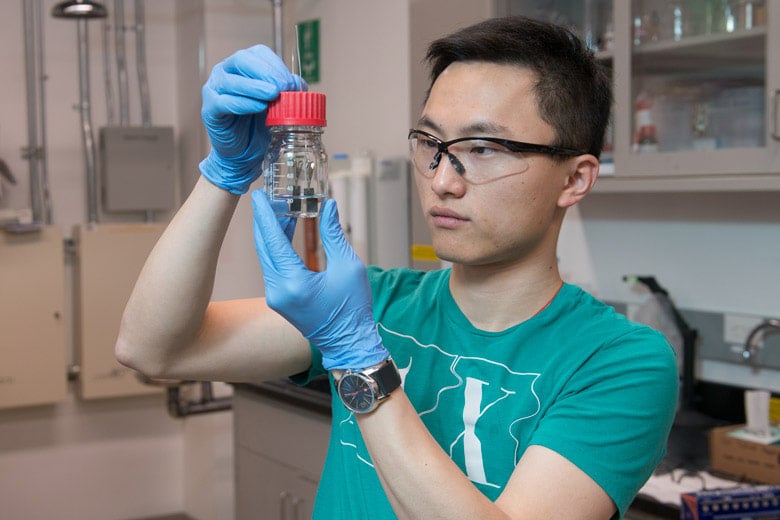

Electrolysis is a process that uses two chemical reactions to generate hydrogen and oxygen gas. Its disadvantage lies in that one of the two reactions is destructive and inefficient. According to Stanford graduate student Haotian Wang, a fifth-year student in applied physics who played a key role in authoring a study about the project, the oxidation reaction required in electrolysis is actually destructive to its catalyst and corrodes its own “fuel.”

The second method of generating industrial hydrogen fuel is reforming natural gas, a process which emits carbon. Reforming natural gas, explained Wang, has harmful consequences.

“The process will produce a lot of greenhouse gases which contribute to global warming,” Wang said. “Also, if you want to use hydrogen as a fuel in a fuel cell, the hydrogen needs to be very pure. But if you have carbon inside, you need to purify it. [Industrial] hydrogen is not pure and not good for fuel cells.”

Typical industrial water splitters involve two catalysts, platinum and iridium, which Wang described as “benchmark catalysts,” albeit rare and expensive. These catalysts spur water-splitting reactions.

To respond to the environmental challenges posed by commercial water splitters, Stanford scientists have developed more efficient water-splitting mechanisms. One such method invented in 2014 by Hongjie Dai, a Stanford professor of chemistry, served as a basis for the single-catalyst water splitter. Instead of involving rare metals such as platinum and iridium, Dai’s invention called only for two catalysts: iron and nickel.

Cui and his colleagues have expanded upon Dai’s technology, using nickel-iron oxide as the single catalyst. The water splitter has been described by Cui and his co-authors as showing promise on a wider scale as a renewable hydrogen fuel that can be consumed by transportation and industry sectors.

By using only one pervasive catalyst, the water splitter significantly drives down the cost of hydrogen energy production. Wang explained that they hope to further increase its efficiency through methods such as raising of temperature of the water.

“Right now, we can run the water splitting for more than 200 hours, but if [we] want to lower the cost even more, [we would have to] run the splitting for 2,000 hours,” Wang said.

“If we can mass produce clean electricity just from sunlight and solar cells to drive water-splitting process to produce hydrogen, the entire process will have zero emissions and the energy will be completely clean,” he added.

Contact Meilinda Sun at meilinda.sun ‘at’ gmail.com.